How to Make a Scratch Built Shifter Model Car

(By request.)

I did this whole thing in one shot in under 2 hours one morning. You can probably do a better one than mine. Heck, I'm sure my next one will be better but I just wanted to get this particular project done and move on.

This is easier than trying to cut or shape a shifter lever out of flat styrene, and as a bonus, you'll be making three or four of them at the same time.

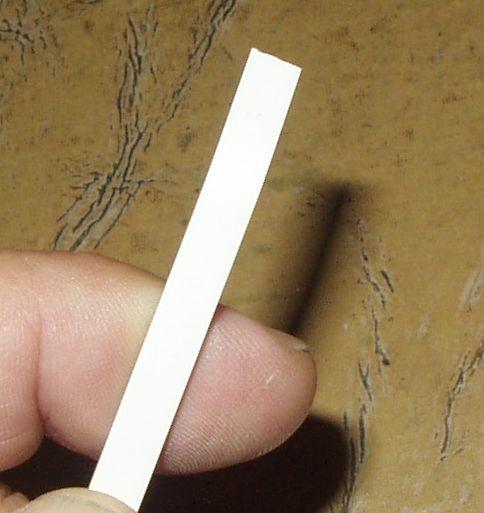

I started with some Evergreen strip styrene like this. I bought a package of the stuff, which looks to be about 2 x 3 scale inches, to make hot rod frames. (Yeah, that'll happen someday.) If you don't have this on hand, I'll tell you in a minute how you can get by with thinner styene.

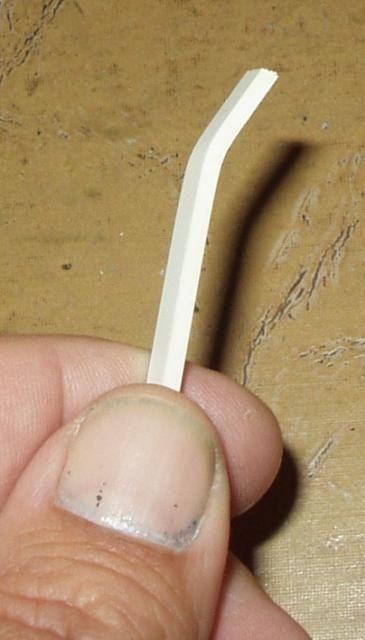

Most Evergreen plastic can be bent cold, with the fingers, but this stuff is so thick that when I tried it, it either broke in two, or cracked horribly at the bend. Tried bending it under hot tap water, which only helped a little, still got cracks. So I stuck an inch or so of the strip into boiling water for six or eight seconds, and then bent it, using pliers. I would have liked just a little more bend and could have probably gotten it either by keeping it in the boiling water a few seconds longer, or even by re-heating this piece and bending it a second time, but for this particular project, this was "good enough" and I drove on.

Don't worry about the length of either side of the bend at this time. You can cut it to whatever length you want later. You're mainly interested in the bend on the backside/inside of the curve. We'll take care of the front side in a minute.

If you don't have this thick styrene on hand, here's another way to do this and you can probably avoid the heating issue. Just laminate up your "billet" from several sheets of .020, .030, 040, whatever you have on hand. Bend the first layer, which will become the inside of the curve, then bend another layer and glue that to the first, then another layer and glue that on top, and so forth. When you have it as thick as the bottom half of the shift lever you want, you're done. Just let the cement dry (I recommend a liquid solvent cement for a solid, permanent bond) and come back to it when it is.

Now just file or sand the front edge of the top half of the shift lever to an eye-pleasing tapered shape. I didn't do anything with the back edge at all. You can also cut the top half to your desired length at this point. Mine was pretty much the length I wanted it to be at this stage, so I didn't have to cut it. Or maybe I did cut it--I don't remember.

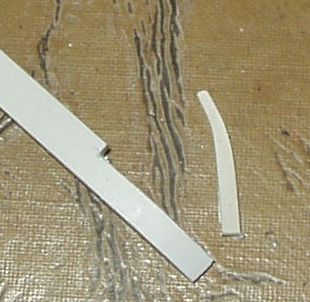

Now you're going to slice one shifter lever out of the billet/blank you just created with a razor saw. . I recommend laying tape on the plastic for a cutting guide. Don't forget to account for the kerf (thickness of the material the saw blade will remove) when you lay the tape. The cut will go smoothest if you start sawing at the bend, rather than at the end, and then proceed "up" and "down" (or outward) from there. Much easier to avoid your cut going off at an angle that way.

After making the "long" cut, go in from the side and cut one shift lever from your blank, still not worrying about the length of the bottom half at this time. NOTICE that I can still cut at least two, maybe three more shift levers from my prepared "billet." How cool is that!

Your cut piece might be a little thick (better too thick than too thin) and/or uneven. It's easily reduced to the desired and uniform or tapered thickness by placing it flat on a file or sanding block and moving it back and forth. TIP: Lick your fingertip so the part sticks to it.

How to Make a Scratch Built Shifter Model Car

Source: http://www.modelcarsmag.com/forums/topic/94431-scratchbuilding-a-hurst-ish-shifter/

0 Response to "How to Make a Scratch Built Shifter Model Car"

Post a Comment